Products

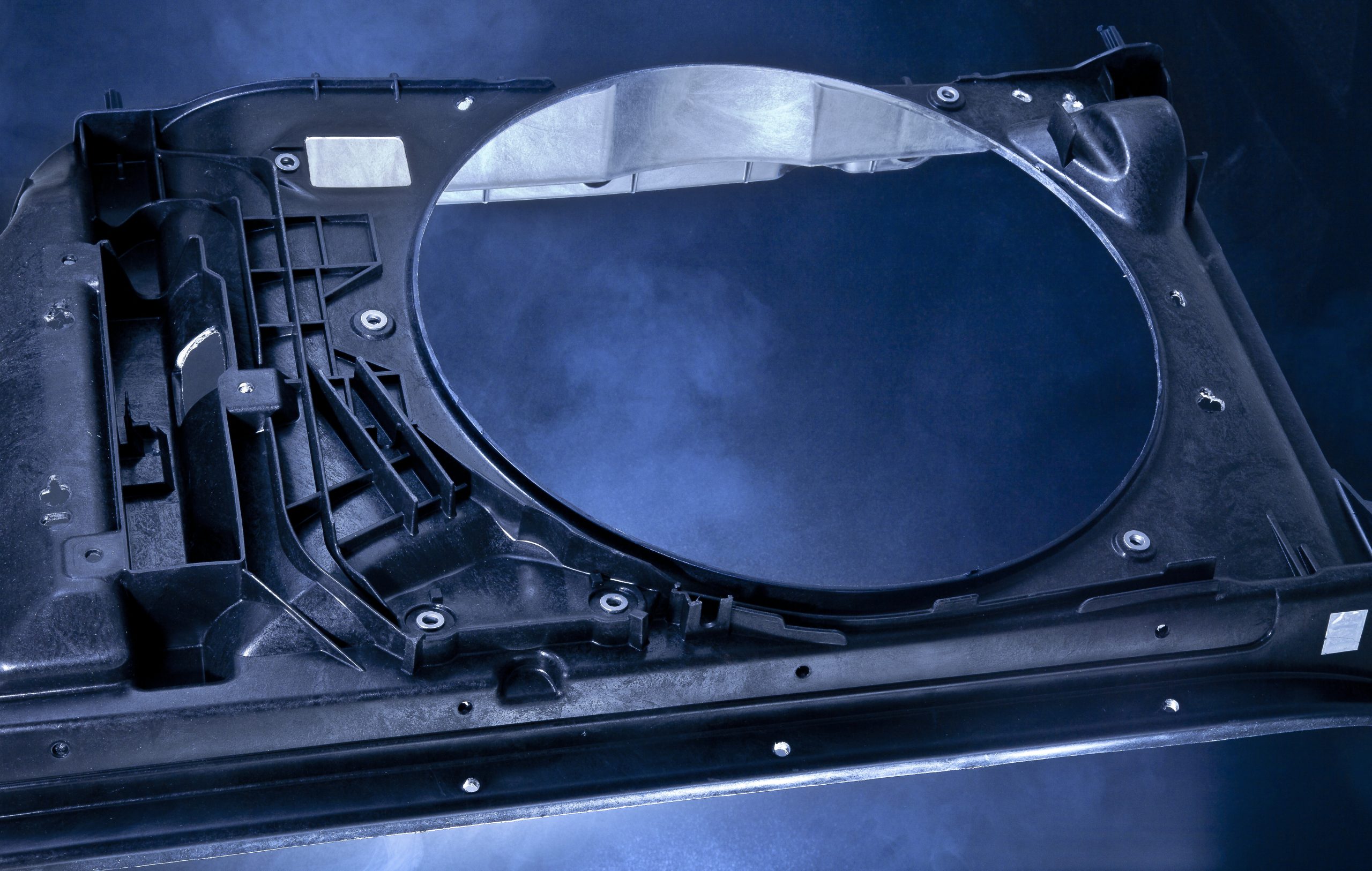

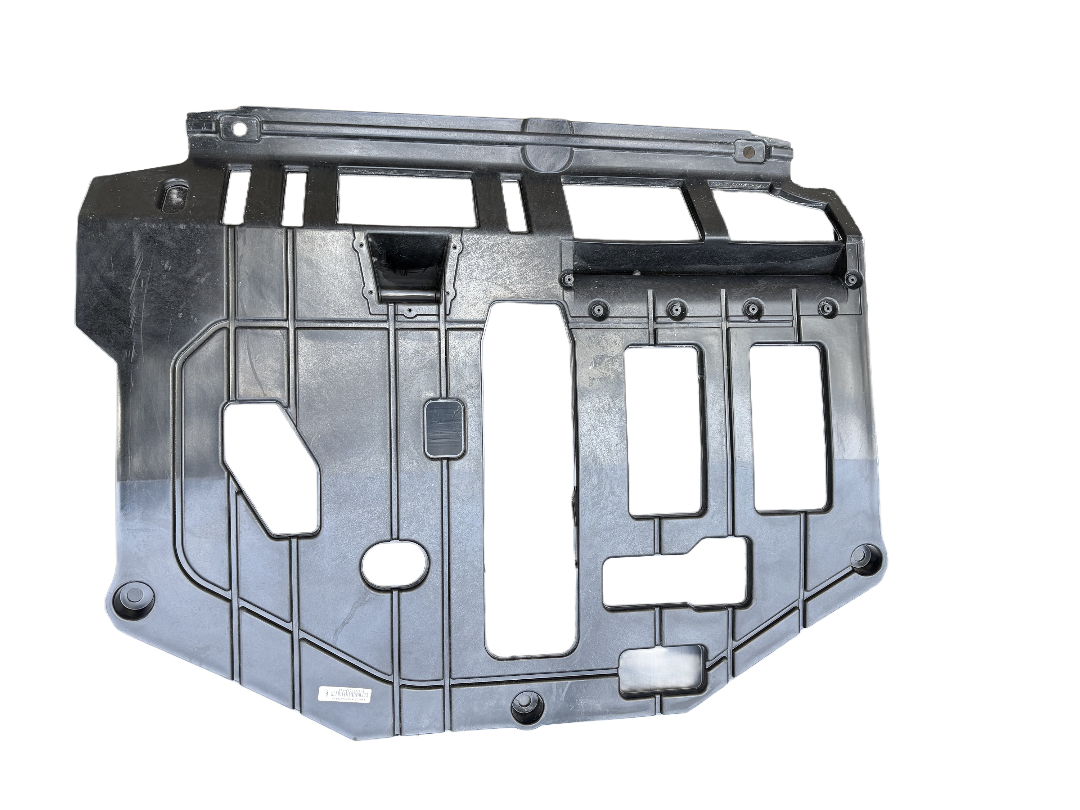

Car parts

Relying on advanced molding technologies of SMC (Sheet Molding Compound) and LFT (Long Fiber Thermoplastic), Noraista Plastic Company has been designing and mass producing high-performance composite parts for the country’s passenger car industry.

Products such as under-engine trays, fan trays, crossbars, and rear bumpers are produced with the aim of reducing weight, optimizing fuel consumption, and improving the structural performance of the vehicle. These parts are designed with low density and at the same time high mechanical strength, thermal stability, and chemical resistance.

All parts are developed in accordance with automotive dimensional and connection standards and are capable of quick installation, easy assembly, and integration with production lines.

During the quality control stages, all parts are subjected to thermal, mechanical, impact, and simulated road performance tests, and their performance is evaluated against environmental, thermal, and mechanical stresses.

Focusing on materials engineering, industrial design, and optimized production, Noraista Plastic offers innovative composite solutions to replace heavy metal parts and takes steps towards sustainable development and improving the quality of domestic automobiles.

Tractor parts

Using advanced SMC and LFT technologies, Noorista Plastic has designed and mass-produced composite tractor parts, including hoods, fenders, dashboards, and footrests.

These parts are designed to lighten the structure, increase durability, and improve mechanical performance. They provide reliable and stable performance in harsh working conditions and agricultural environments by having high resistance to continuous stresses, impacts, corrosion, and dust penetration.

The production process at Noorista Plastic is carried out under strict quality control and in accordance with international standards of the agricultural machinery industry so that the final parts meet the needs of tractor manufacturers in terms of dimensions, mechanical properties, and surface finish, and allow for quick installation and easy serviceability.

Noorista Plastic, relying on engineering expertise, industrial design, and modern production equipment, offers efficient, lightweight, and durable solutions for replacing metal parts in agricultural machinery.

Commercial vehicle parts

Noraista Plastic Company, using advanced SMC and LFT molding technologies, has designed and manufactured body parts and protective covers for heavy trucks and tractors.

Among the products in this series are upper and lower side wind deflectors (left and right deflectors), roof wind deflectors, shrouds and left and right flaps, which are designed and manufactured with the aim of improving aerodynamics, effectively directing air flow, reducing air resistance, and protecting against dust and rain.

Using engineered composite materials with long fibers and resistant resin, these parts have features such as high strength, resistance to impact, corrosion, and UV rays, and are easily installed in production or repair lines.

All parts are manufactured in accordance with current industry standards and are marketed after durability, impact, and performance tests in harsh conditions to increase the lifespan of heavy-duty transportation fleets, reduce maintenance costs, and improve fuel efficiency.

Rail transportation parts

Noorista Plastic Company, relying on advanced technologies for the production of engineering composites, also has an effective presence in the field of rail and urban transportation.

The unique properties of composite materials, such as high strength, light weight, mechanical durability, and especially non-flammability, have made it possible for the company’s manufactured parts to be a safe and reliable option for use in train carriages, subways, and urban transportation systems.

By complying with safety and fire standards (such as EN-45545), Noorista Plastic has been able to produce parts with stable performance against heat, impact, vibration, and corrosion, which, in addition to reducing the overall weight of the structure, also help increase safety and energy efficiency in the rail transportation fleet.

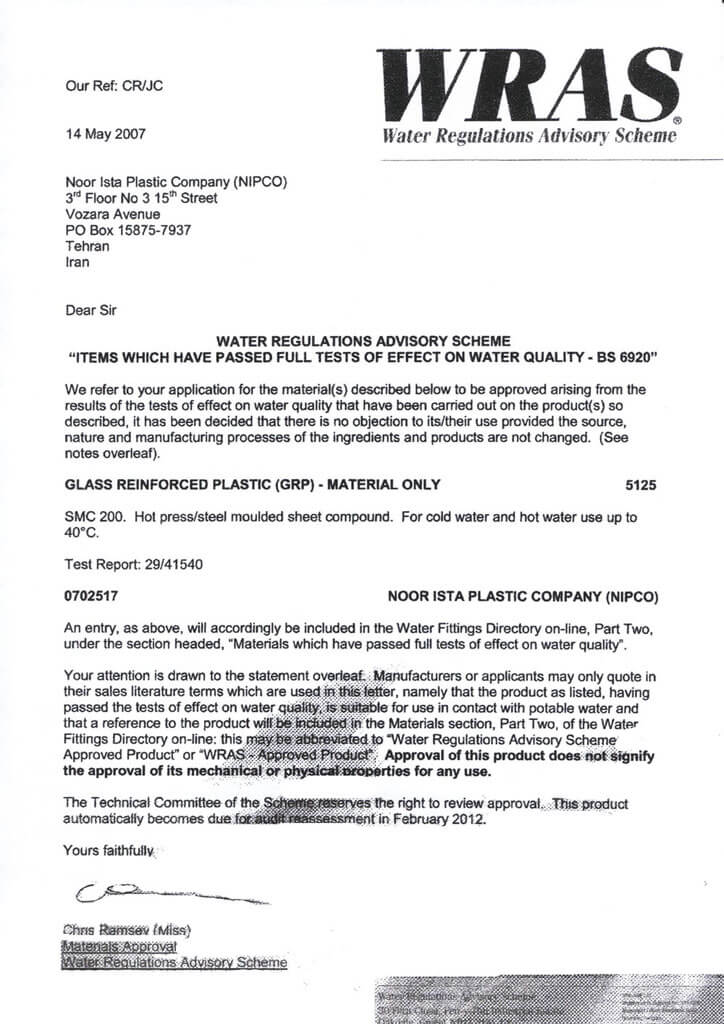

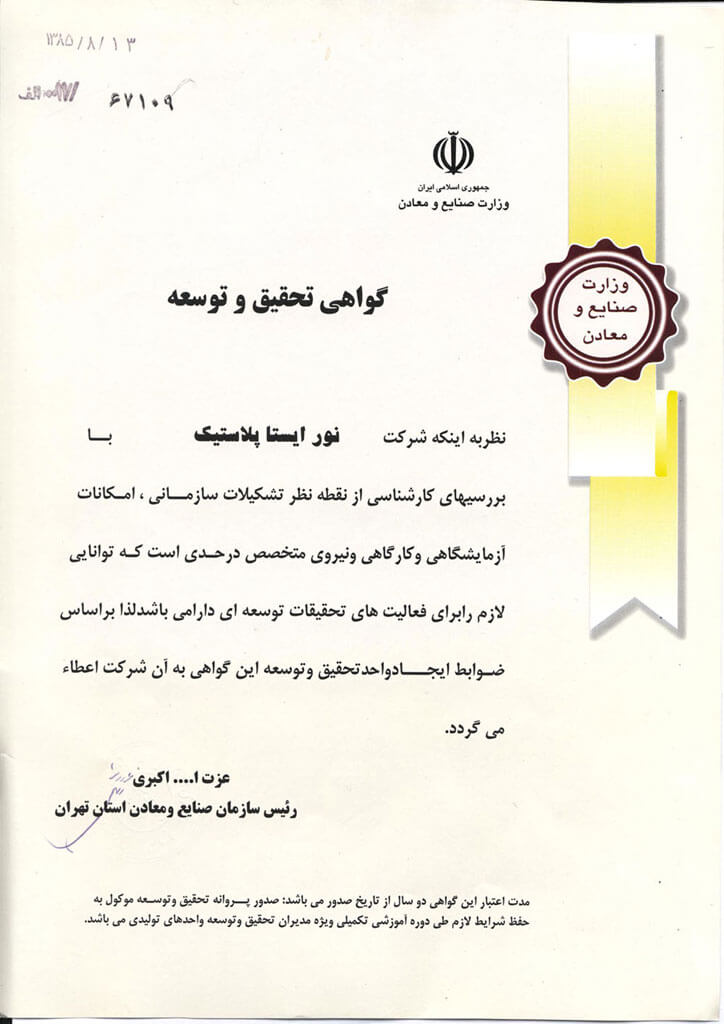

Quality certificates

As a strong and reliable manufacturer, Nipco supports high-quality products by using local and international quality standards such as ISO/TS 16949:2009 and EN ISO 9001 to gain the trust of its domestic and international customers.

The use of standards helps in creating safe, reliable and good quality products and services. These standards help businesses to increase productivity while reducing errors and waste. By allowing direct comparison of products from different markets, they facilitate companies to enter new markets and help develop global trade in a fair manner. These standards also protect consumers and end users of products and services by ensuring that certified products comply with minimum standards set internationally.