About NIPCO

Noor Ista Plastic Company (NIPCO) was established in 1998 in Iran. The company’s factory is located on an area of 33,000 square meters in Eshtehard Industrial Park.

Currently, NIPCO is the largest and most equipped composite products manufacturing unit in Iran that produces various composite parts related to the automotive and energy industries. Based on customer orders, it produces quality products using BMC, GMT, LFT, SMC and RTM methods with the experiences of experts.

NIPCO’s customers are confident in its capabilities and know it as a strong composite parts manufacturer with good quality, which is confirmed by international and domestic standards such as PSA France, ISO / IATF and the standards of “Sapco Iran Khodro” Engineering Company and “Sazeh Gostar Saipa” Engineering Company.

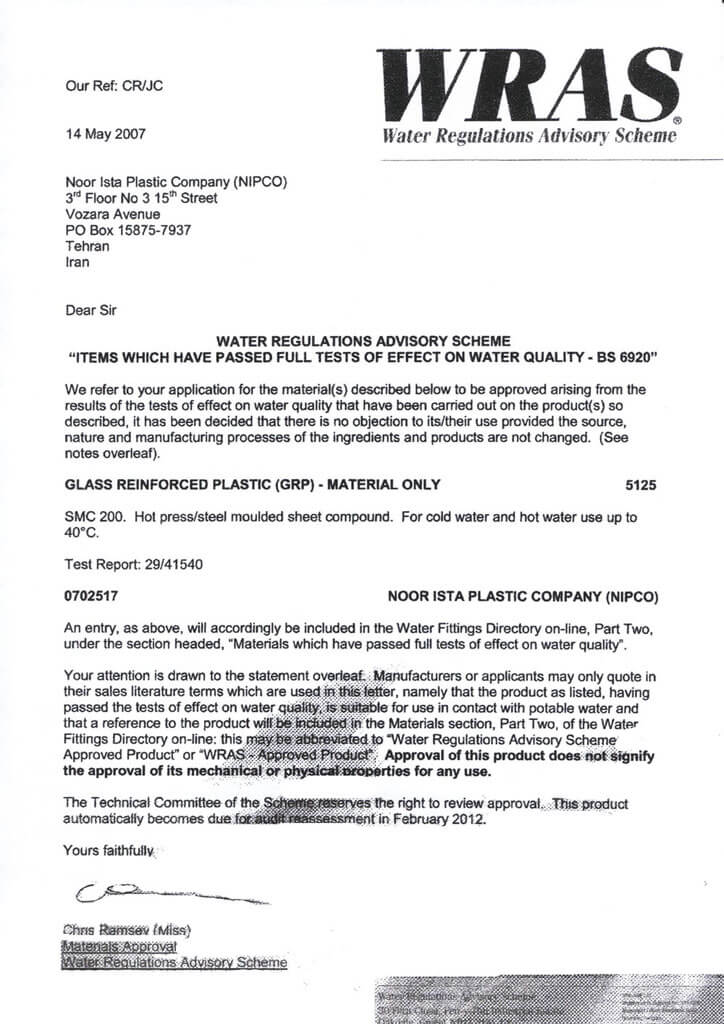

Quality certificates

As a strong and reliable manufacturer, Nipco supports high-quality products by using local and international quality standards such as ISO/TS 16949:2009 and EN ISO 9001 to gain the trust of its domestic and international customers.

The use of standards helps in creating safe, reliable and good quality products and services. These standards help businesses to increase productivity while reducing errors and waste. By allowing direct comparison of products from different markets, they facilitate companies to enter new markets and help develop global trade in a fair manner. These standards also protect consumers and end users of products and services by ensuring that certified products comply with minimum standards set internationally.

Technologies

Composites are a combination of two or more materials with different physical and chemical properties. When combined, they create a material that is specialized to perform specific tasks, for example, being stronger, lighter, or resistant to electrical shock.

Composites can improve strength and stiffness, and the reason they are used instead of traditional materials is that they change the properties of the base material and are used in many applications.

Currently, Nipco uses RTM, GMT, BMC, LFT, and SMC technologies.

Quality Control

The area of the NIPCCO laboratories is approximately 400 square meters and is equipped with all the necessary facilities to perform any relevant tests on composite parts. With ITRAK and SAPCO method certifications, it is considered one of the largest and most equipped laboratories of its kind.

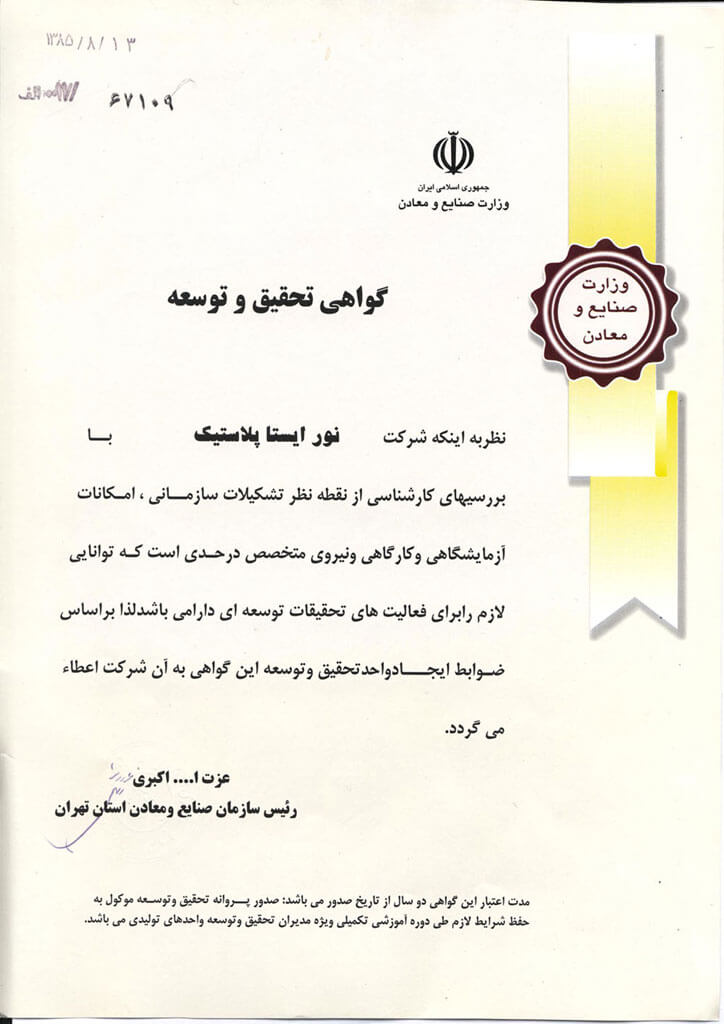

Research and Development

Research and Development is where our visionary team dares to imagine developing innovative technology that will have a lasting impact on the future of quality.

Using their collective expertise in engineering, our R&D professionals work on new genesis methods to improve existing processes as well as organizational knowledge.

Laboratory

As one of the key infrastructures in ensuring product quality, Noraista Plastic Company’s quality control laboratory, utilizing advanced and specialized equipment, performs the process of testing and evaluating the properties of composite parts produced using SMC (Sheet Molding Compound) and LFT (Long Fiber Thermoplastic) methods in accordance with industry standards, especially SAPCO Grade A requirements.